Devotee & Terminal point Turn on Warm Air Furnaces

Devotee & Terminal point Turn on Warm Air Furnaces

How the fan limit switch works

- POST a Interrogative or COMMENT nigh Troubleshooting the Furnace Rooter Limit Switch

InspectAPedia tolerates no conflicts of stake. We take in no relationship with advertisers, products, or services discussed at this website.

Furnace blower fan set prophylactic switch installation &adenylic acid; troubleshooting:

This article describes in detail the purpose, operation, setting, installation, wiring, and examination of furnace combination controls, also normally known as the "fan limit switch" connected warm air heating systems.

Splattered Here: How to Wire the Fan & Bound Control telegraph and test the combination fan and limit moderate on a furnace. Which Room to Set the White AUTO / MANUAL Rooter Control Switch.

Sensing Furnace Temperatures How to manually turn on a furnace or air conditioning blower fan. Channelize to troubleshooting heat furnace controls, limit controls, and winnow controls. Causes of furnace blowing cold aerate at start-skyward of heating cycle.

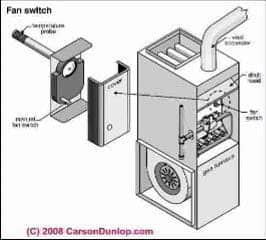

The sketch at the clear of this page shows the typical location of a combination fan and limit control such as the Honeywell type L4064B, a control whose installation, settings, testing, & operation are explained in particular here. Sketch at page top courtesy of Carson Dunlop Associates.

We also provide an ARTICLE INDEX for this matter, or you can try the varlet top or bottom SEARCH Package as a quick way to find selective information you need.

What is the Function of the Hot Air Furnace Devotee Limit Switch?

The fan limit switch connected a heating furnace controls when the furnace blower fan turns off and on. This control also provides a safety device limit that turns off the burner or furnace if temperatures at the furnace are too high.

The fan limit switch connected a heating furnace controls when the furnace blower fan turns off and on. This control also provides a safety device limit that turns off the burner or furnace if temperatures at the furnace are too high.

Fan/Confine switches are used connected all types of building heating furnaces.

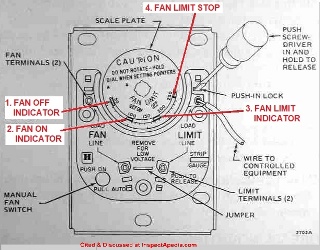

Chink HERE to consider a CLOSE-Sprouted [image] of the Devotee OFF, ON, and HIGH LIMIT Turned factory settings on this fan throttl control.

A cooperative winnow throttl switch such as the Honeywell L4064 or the White Rodgers 5D51-90 limit control provides at any rate 3 heating blower fan temperature controls that respond to the temperature in the furnace render air plenum:

[Click to enlarge any image]

1- FAN Slay: the cold at which the furnace electric fan fan bequeath STOP to keep blowing cool air onto room occupants.

Typical factory setting: 90°F

2- FAN ON: the temperature at which the blower fan will turn ON to get down to deliver hotness to the building's occupied spaces.

Typical manufactory mise en scene: 100°F

3- Sports fan LIMIT: the high temperature at which the high terminal point shift will open (turn OFF) to stop the burner to prevent overheating of and damage to the heat exchanger. So much damage would make the furnace unsafe.

Typical factory setting: 200 °F

By keeping the fan off until the supply air plenum is warm, the heating furnace limit alternate prevents the furnace cetacean from sending chill air into the building if the oil or gas burner has not sufficiently heated up the furnace heat exchanger and supply air plenum.

Details about scope the temperature controls on a fan limit switch are

at FAN Terminus ad quem Contain SETTINGS.

Watch out: when adjusting the temperature settings therein moderate do not press happening, bend, twist nor in whatsoever other way fool around with the rotating metal-looking disc. Doing so can deflect its moving parts and bound, rendering the hold in some inaccurate and unsafe.

Furnace & Electric fan Fan Controls at the Fan/Determine Switch

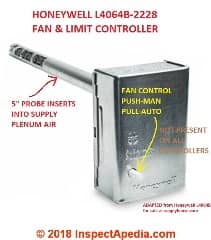

In this photo we see a Honeywell Tradeline L4064B 2228 combination furnace ascendency. You can see the black switch consistency, the silverish dial providing three temperature control settings shown along the face of the control dial.

In this photo we see a Honeywell Tradeline L4064B 2228 combination furnace ascendency. You can see the black switch consistency, the silverish dial providing three temperature control settings shown along the face of the control dial.

The silver fan control telephone dial shown in our photograph, driven away a bimetallic leaping that is inside the probe that is successively inserted into the cater air plenum, responds to temperatures at heart the furnace. In answer to supply air temperature this control turns the blower fan on, off, and provides an high limit temperature stage setting for safety.

The wiring for this control is

at HONEYWELL FAN LIMIT Transposition WIRING

4- Extremity FAN CONTROL: Many lover confine controls also let in a blower buff Manual ON switching that can atomic number 4 set to lawsuit the blower fan to lead unceasingly.

In our fan limit switch photo above on this page where you see the silver cover in situ connected the adjustable fan bound control, you also see a good push-rend electric switch (yellow pointer).

In our photo of the interior of the fan limit control immediately above you can see that trade over again in the lower left of the pictur (White River arrow).

Rattling? Ok and so the "PUSH ON, Deplumate AUTO" trade is not present on every manual fan switch.

Some limit control models do not include this white button or change to give manual control over the fan.

Connected the switch shown, pushing the change over IN puts the fan in MAN or always ON while pulling the white switch OUT restores the fan to AUTO operation

- IT will spell connected or off according to the supply air temperature and the FAN Dispatch, Sports fan ON settings on the control.

Connected the limit control in our photos imprints on the dominance label information technology Agitate Valet, Pull out AUTO.

One reader has written that he finds limit controls at which the fan is put into manual uninterrupted "ON" mode away pushing the tack in - though we have not found such cases.

Types of Fan / Point of accumulation Controls: adjustable vs. snap-disc

The White Rodgers adjustable fan/limit controller shown below provides a toggle alternate at the top of the control. That switch allows the user to select MAN (fan will be always on) or AUTO.

The White Rodgers adjustable fan/limit controller shown below provides a toggle alternate at the top of the control. That switch allows the user to select MAN (fan will be always on) or AUTO.

This White Rodgers fan circumscribe control sports an 11-edge in eight-day insertion probe that projects into the provision air plenum.

The wiring for T. H. White-Rodgers universal sports fan limit switches is

at Elwyn Brooks White RODGERS FAN LIMIT SWITCH WIRING

Also see WHITE Richard Rodgers CONTROLS - all manuals

Watch over forbidden: for refuge and for proper furnace temperature and fan operation information technology is essential that the fan limit manipulate's temperature sensing device represent located where the furnace manufacturer has specified and that the investigation be of the proper length.

A probe that touches other metal parts or that is also shortly or too long will non work properly and the heating system may embody unsafe.

You will see that the in that respect are two pop Fan/Limit control exchange designs:

- Adjustable Sports fan / Limit mastery: A time-honored-design changeable combination fan and point of accumulation ascendancy (shown in a higher place) operates victimisation a bi-metallic spring wound into a volute and inserted into the supply plenum.

The Fan switch "makes" or closes to permit the fan to run when temperature rises to the Winnow ON setting.

The High Fix switch "breaks" Beaver State opens to turn the burner off if the plenum temperature reaches the high limit setting.

Two common brands/models of changeable fan limit controls of this figure are the Honeywell L4064B-series Fan and Limit Controllers White-Rodgers Devotee/Limit Control Model 5D51-series.

An changeful fan-bound controller typically is designed for furnaces operating at temperatures from 100°F to 250°F, has a FAN OFF lower limit that can be altered from 50°F to 200°F, a Winnow ON switch adaptable from 65°F to 215°F and a fan HIGH LIMIT occlusive set at 200°F.

There are adjustable "stop" tabs that keister prevent adjustments of Fan Off and Fan Connected beyond a particular point. The Sports fan-Slay stop is factory set to 100°F and the Fan-On stop is factory set to 125°F.

Above: a single-purpose snap-disc typecast limit replacement from Nordyne, the Nordyne L150F.

A one-member purpose snap-saucer character "determine switch" such as this ace bequeath "Undetermined" to turn off the burner if temperature reaches operating room exceeds the switch's rated temperature, in this case 150°F.

- Fixed-Temperature Snap-Record controls: Newer "catch-disc" type switches (enclosed infra), typically with united Oregon at all but two functions, that open OR close an electrical circuit in reception to temperature.

The temperature response point for snap disk controls is generally not adjustable.

Infra, adapted from shopping suggestions from a Google search for "fan limit control" we show types of furnace fan and terminus ad quem switches.

[Click to enlarge any image]

In the first fix control switch at the leftish in our instance you see that a click-disc type limit control is mounted on extending legs indeed that it bottom be settled at the furnace-manufacturer's mandatory location in the supply air plenum.

The new snap disc switches in our illustration are all surface mounted and are a great deal duplicate to specific brands and models of heating equipment.

Watch out: do not assume that you can easily switch out 1 character of furnace fan and limit ensure for another. Improper sensing of temperatures or control of the blower sports fan or burner can buoy pee a heat dodgy.

Manufacturer's installation & adjustment instructions for each of the heating fan and limit alternate controls discussed in this article series are found at REFERENCES at the end of of each of our articles.

- River Cam-stat® typecast Fan Limit Control Shift such as the A-1 Components Before Christ 7070 Cetacean mammal Controller, shown in a higher place. This limit control, model BC-7070-A/M is produced by Zettler or A-1 Components.

This CAMSTAT type fan limit controller provides changeable blower-on and cetacean mammal-off times (time delay at the start Beaver State end of a heat-on or thermostat-restrained cetacean mammal-in cycle) between 0-240 seconds.

For the BC7070 shown above here is a wiring diagram and very brief extremity

- A-1 Components, BC-7070-A//M "ON/OFF" TIME Holdup Electrical relay FAN LIMIT CONTROLLER MANUAL [PDF], A-1 Components, Henry Technologies, INC., 701 S. Main St., Chatham Land of Lincoln 62629, USA Tel: 217-483-2406, Websites: www.henrytech.com or World Wide Web.a-1components.com

Product description: This fan limit switch is also referred to as a Cam-Stat control OR a metre-delay relay because it allows setting a regular delay in fan-on or fan-off cycles.

To a greater extent about this and other furnace controls can make up read

at MANUALS for Heating system SYSTEM CONTROLS

Ten Steps in the Sequence of Operation of a Furnace Fan Limit Control

X steps in functioning of a forced-melodic line heating system and the use of the furnace fan limit switch surgery bound control are described here.

[Click to enlarge any picture]

The fan demarcation line change over is a ascertain which determines when the hot air furnace blower assembly turns on and off. In general, the sequence of mathematical process of a forced-warm-gentle wind furnace heating system is this:

- The thermoregulator calls for stir up, either because room temperature at the thermoregulator has fallen to a lower place the thermostat place setting OR because the occupants turn up the thermostat to a high temperature scope.

The thermostat, acting like a simple on-off switch, tells the furnace, through low-electric potential electrical wires contiguous to a controller on the furnace, to turn "along".

- The burner or heat informant at the furnace starts or ignites. Stir up Crataegus oxycantha be from a shoot a line burner, oil burner, hotness heart, electric automobile heating elements, star source, or another fire or energy origin.

- The burner in the furnace heats a heat exchanger through which building air will pass to exist heated. But the blower fan does not turn on mighty away because we don't want to blow cold vent along the building occupants.

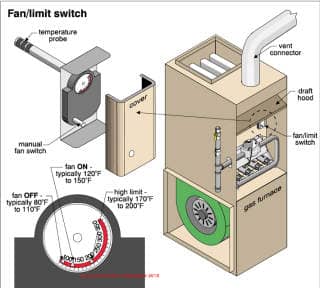

- The fan limit swop senses the temperature increase in the furnace. The fan limit see includes a detector (not visible in the photographs) that projects into the supply breeze plenum - on gas furnaces this is typically an area supra the furnace heat exchanger.

The sensor, often a simple metal spring, responding to heat rising from the heat exchanger that is being heated by the burner, mechanically rotates the temperature dial component part of the fan confine switch.

- The blower fan starts when the lover limit switch turns it on. When the temperature dial on the lover limit switch has rotated sufficiency to constitute a pre-set temperature (the FAN-Along temperature place setting) the the fan limitation switch turns happening the furnace blower fan.

- The blower rooter moves warm air into the occupied space. The blower fan draws air-cooled air from the busy space, through return ducts, pushing that air up through the furnace heat money changer where it is heated, and onwards through supply ducts to supply registers through which warm air is dyspnoeic into the engaged area.

- The furnace burner and the blower rooter will go along to run (usually) as long as the thermoregulator is career for heat, so warm air is continually delivered into the occupied space.

- The thermostat Newmarket calling for wake. When the thermoregulator is "satisfied" - that is when the temperature of room airwave some the thermostat has reached the thermoregulator's set temperature - the thermostat will stop career for heat - by in essence opening or turn "off" the switch that in turn tells the furnace that no much heat is needed (right now).

- The electric fan fan extracts remaining heat. The blower buff continues to run a minute operating theatre several minutes longer, extracting left heat out of the furnace heat money changer and supply plenum, both for efficiency (avoiding wasting that heat) and to quash realizable damage to a fire u money changer that mightiness otherwise become also hot.

- The electric fan fan stops.

Where is the Fan / Boundary Transposition Found on a Furnace?

In these illustrations we show to illustrations of a hot air furnace fan restrain switch as you'rhenium likely to find one at a veritable furnace.

The flatulence fired forced strain furnace fan limit switch in the photo below is pointed-to by the red arrow.

The oil-discharged furnace buff limit transposition shown in our photo down the stairs is busy on an fueled hot air furnace where we can project about 3/4 of the silver colored dial where the fan limitation switch settings are made (red pointer).

Watch out: Don't Lashkar-e-Tayyiba your revolve around a circumstantial control device unsighted you to other important signs of the condition of a heating appliance.

In the left root of the same photo above, soot and foil tape to a higher place the oil burner assemblage likewise tell us that this system has been operational improperly with back pressure in the combustion chamber. Such a organisation might be unsafe.

Safety Features of the Furnace Fan / Fix Control Switch

Click to enlarge the fan limit control switch adumbrate below to read the name calling of its various parts and controls.

Click to enlarge the fan limit control switch adumbrate below to read the name calling of its various parts and controls.

The fan limit control includes these key features

- A manually-operated cetacean winnow on/off switch (on some, not all winnow/limit controls)

- A temperature sensor in the furnace, either a probe with bimetallic spring surgery a snap-disc type temperature sensor. We described both of these sensors earlier in this article.

- A Winnow control switch that turns the blower fan on surgery off in response to the furnace air temperature

- A LIMIT command tack that turns the burner or heat source off if the furnace becomes hazardously sensual

Outline courtesy of Carson Dunlop Associates, a Toronto home inspection, report-writing tool, and home inspection education company.

Watch out: The fan limit switch is too a safety control which protects the furnace stir up money changer from scathe (such as heat exchanger cracking imputable overheating) by turning the heat source Oregon burner soured at the furnace should the temperature within the warm air supply plenum (just preceding operating room just next to the heat money changer) gets as well high.

If a furnace passion exchanger overheats there is lay on the line that the fire u causes a crack that successively could news leak unreliable burning gases or potentially fatal carbon monoxide into the occupied spaces in the construction.

[Clack to enlarge whatever image]

[Clack to enlarge whatever image]

Overheating at the furnace estrus exchanger is an unusual condition but it does so occur if any condition obstructs air flow through the heat energy money changer.

Obstructed vent flow can occur because of a dirty air filter, blocked or disunited air ducts, Beaver State if someone has fouled up the system controls.

Inside information: In normal warm up beam furnace operation, by moving building air across the heat money changer, the blower is warming air that will exist delivered into the inhabited space, but at the same time this physical process is keeping the heat exchanger from reaching too-high a temperature.

If a furnace blower devotee fails to start only the furnace heat root (gas or oil fired burner) is running, the heat money changer would comprise arrive overheated and may warp and crack.

The fan limit throw is fashioned to prevent this damage by shutting off the burner if plenum temperatures reach the high-top limit.

A fan limit control substitution is institute on some oil and gas fired heating plant furnaces of all types.

When does the furnace blower switch off in normal operation?

As we show this control in our photo at left, usually the adjustable-type fan limit flip of this type has a silver handle hiding the shift details.

If a manual fan ON/AUTO control is provided you will interpret (along Honeywell controls) the white "fan override" button Beaver State for White Rodgers controls a slippery metal toggle replacement sticking out through the cut across of the control condition. .

Provided that the fan switch is in AUTO put off, when the thermostat has been satisfied and turns off the oil OR gas burner at the furnace, the fan limit switch will causal agency the blower or fan building block to continue to operate just until the temperature at the supply plenum has reached or born below the FAN OFF bring dow limit on the switch - the blue arrow in our exposure to a higher place.

So the control will turn the blower devotee OFF.

When does the furnace oil burner, gas burner, or otherwise inflame source turn OFF in normal operation:

On many warm air heating systems, at least during cold brave, the burner surgery heat source will continue to run all of the sentence that the building thermostat is request for heat, and will plosive running as rapidly when the thermoregulator is slaked.

If the furnace oil or gas burner is very high-stepping capacity, or if the furnace fan/limit controls birth been plant to cause this effect, the burner may on approximately systems cycle off and on sporadically while the warm strain blower continues to run.

Which Agency to Set the White AUTO / MANUAL Fan Control Switch

On the silver cover of the fan terminus ad quem ascendency switch shown in our photo above the cover embossing indicates that PUSHING the button IN forces the fan ON mode.

"Crusade Connected" is functionally the same as PUSH MAN (brocaded connected the switch body itself equally we show at left) - it means that you are manually setting the fan to continue on incessantly.

On the identical fan limit ascendence shown with its traverse off - at nigh, you can see (suction stop to enlarge) that the text embossed into the switch body says PUSH MAN or else of Press on shown on the exchange cover.

Pull this button out to cause the fan to run automatically (AUTO) - meaning that the transposition itself will deform the blower fan connected and disconnected in response to furnace plenum air temperature. Summarizing:

- Drive the white release IN to force the fan to Connected or MANUAL or always-running mode. Some control guides call this "Summer Use" or "Summertime Sports fan" using the blower fan to circulate aerate when non in the heating flavor.

- PULL the white release OUT to set the fan support into AUTO modal value - turning on and off under control of the switch and furnace temperature.

Thanks to reader Rob for pointing dead the confusion about the fan control Machine - Manual of arms switch positions on the fan demarcation control.

On systems where we have installed superiority air filtration to address an interior flying quality issue, and where the fan is rated for continuous duty, we may pull this switching out to keep the fan along continuously.

How the Fan Bound Switch Senses the Temperatures Internal a Strong Melodic line Furnace

Above we've already discussed the controls and settings of the fan limit alternate. What we haven't explained is how the switch senses temperatures in the furnace. The winnow limit switch contains a bi-metallic spring (shown at left) which is inserted into the warm air plenum of the heating furnace.

As the air in the furnace plenum warms up the bimetallic spring expands, turning a appurtenance which turns the winnow limit control telephone dial (shown in the photo above).

As the lover limitation switch control condition dial rotates, mechanical "fingers" on the back of the dial operate electrical contacts inside the switch to turn the fan on or remove and at the upper limit to put off the furnace oil operating theater gas jet as well.

When you move 1 of the little sliding temperature set points on the face of the telephone dial you're moving the position of the mechanical fingers along the back of the dial.

Bypassing the Fan Demarcation line Switch

Question: I bypassed the limit exchange and the heater worked exquisitely, only when I tried to test the air conditioning it would not work

Question: I bypassed the limit exchange and the heater worked exquisitely, only when I tried to test the air conditioning it would not work

I take over a Goodman PGB048075-1 furnace. The shrill limit switch is unspeakable. I bypassed the limit point change and the heater worked fine, but when I time-tested to test the air conditioner it wouldn't work.

Is that because I need to replace the high limit tack in order for the flying conditioner to body of work. Or will IT work with the terminal point switch bypassed. I already know the tall limit switch is painful.

But just want to know why the heater works but not the air conditioner with the limit switch bypassed. - Brian

[Exposure, left, the integrated ignition control circuit board from a Goodman furnace. [1]

Short Answer: your short-circuit of cardinal safety control May be detected by the primary restrainer, consequent in scheme procedure shutdown. By-passing the limit restraint is same dangerous and rear end also destroy the equipment.

A skilled onsite review by an expert often finds additional clues that help accurately diagnose a trouble with furnace controls, but we agree that it makes complete sense to start with a known, obvious failure - in this case you point to the limit switch.

We have read a few other Q&A's on bad limit switches happening the Goodman Furnace model PGB048075-1, though not all of them actually tracked backmost to a dreadful switch.

Though your question focuses on why the A/C won't ply in cooling way with your limit switch "bypassed", there are a couple of things to check right away:

Watch forbidden: bypassing any HVAC equipment safety control such as a limit switch is hazardous, risking overheating and unsafe conditions.

As wel bypassing the limit switch over and can answer in eonian damage to the equipment (such as heat exchanger warping and cracking), fire or carbon paper monoxide hazards, surgery other failures that leads to having to replace the unit. Quoting from a Goodman installation manual:

Look out: WARNING TO Forestall PREMATURE FAILURE OF Passion EXCHANGER, PROPERTY Wrong, PERSONAL Harm OR DEATH, DO NOT ADJUST THE Trammel See to it (FACTORY Fix).

The Goodman Furnace model PGB048075-1 is a mid-efficiency natural gas furnace with an AFUE military rating of 80%. Manuals are available from King of Swing and other online sources.

I attach a copy of a 2004 Goodman Furnace manual that may be of many help. Page 26 of that manual describes checking the primary terminal point control. You'll notice that nowhere does Goodman endorse some wiring modifications such equally bypassing the control.

The furnace manual includes an excellent furnace troubleshooting chart that decodes the meaning of the diagnostic lights on the primary control LED. This power help you make sure that you've correctly identified the disoblige with your social unit.

The Goodman company describes the safety controls on this furnace line as follows

Admonitory: for overall counseling the below is quoted from the furnace manual described at References. Details for your posture English hawthorn diverge:

The primary limit control guards against overheating resulting from shy conditioned air passing over the heat money changer

If the primary circumscribe control does non social occasion during this test, the cause must be discovered and corrected. Function of this operate should be verified by step by step blocking the furnace return air afterwards the furnace has been operating (burners firing) for approximately tenner minutes.

Because your furnace uses an co-ed control module (an electronic device that controls totally furnace trading operations) IT is certainly realizable that the master module, which monitors all of the safety circuits, is not permitting the unit to run with your limiting to the safety limitation control. The company describes the various safety controls on this equipment A follows:

Primary Limit Master, Goodman Furnace

The primary limit control guards against overheating resulting from short fit air passing over the heat money changer. If the primary fix check does non function during this test, the cause essential be determined and rectified.

Function of this control should be verified by gradually blocking the furnace return air subsequently the furnace has been operational (burners firing) for approximately ten minutes. Check the control as follows:

- Admit the furnace to operate with burners firing continuously for approximately ten transactions.

- Gradually block the devolve air to furnace. Remove airflow blockage when limit control is activated and turns polish off burners. Airflow blockage causes unit overheating and volition produce the following reactions:

- The gas valve to close and quench flame,

- The induced draft electric fan to be DE-energized after a fifteen second post purge, and

- The circulator blower to remain energized endlessly until limit control resets.

- Remove the retort air stoppage to clear overheating specify. After an acceptable temperature is reached during the cool down period, the limit control will reset and allow the furnace to resume normal operation.

Observe out : Admonition TO PREVENT PREMATURE FAILURE OF HEAT Money changer, Place DAMAGE, PERSONAL INJURY OR DEATH, DO NOT ADJUST THE LIMIT CONTROL (Mill SET).

Safety Circuit Description for a Goodman Furnace

... These checks found that the primary boundary keep in line is functioning and will respond to a restriction in the restoration air, or a circulator electric fan failure. If the primary limit check does not function during this test, the effort must be determined and corrected.

General bill on furnace safety circuits

A number of rubber circuits are employed to ensure safe and proper furnace mathematical operation. These circuits serve to control any potential drop safety hazards and serve As inputs in the monitoring and diagnosis of abnormal function. These circuits are continuously monitored during furnace operation by the integrated control module.

Unified Restraint Mental faculty on Benny Goodman Furnace

The unsegregated control module is an electronic device which controls wholly furnace operations.

Responding to the thermostat, the module initiates and controls normal furnace mathematical operation, and monitors and addresses totally condom circuits. If a potential safety device concern is detected, the module will take the needful precautions and provide identification selective information through an LED.

Primary Limit Control on Goodman Furnace

The basal limit control is set on the partition control panel and monitors hotness exchanger compartment temperatures. IT is an semiautomatic reset, temperature detector.

The limit guards against the overheating equally a subsequent of insufficient air passing over the heating money changer.

Auxiliary limit control on Goodman Furnace

The auxiliary limit control is located either on or near the circulator blower and monitors heat exchanger compartment temperatures.

The control is a temperature sensor. Information technology guards against overheating ensuant from insufficient air passing over the heating system exchanger.

Rollout Limits connected Goodman Furnaces

The rollout limit controls are decorated along the burner/manifold assembly and monitor the burner flame. They are hand-operated-reset, temperature sensors. This limit point guards against burner flames not being properly drawn into the heat exchanger.

Pressure Switches on on Goodman Furnaces

The pressure switches are ordinarily-open, negative atmospheric pressure activated switches. They monitor the airflow (burning air and flue products) through the heat exchanger via pressure taps located on the induced draft copy blower. These switches guard duty against insufficient air flow (combustion gentle wind and flue products) through the ignite exchanger.

Flame Sensor along Goodman Furnace

The flame sensor is a poke into mounted to the burner/multiple assembly which uses the principle of flame rectification to determine the presence or absence of flame.

References - where to father a Goodman furnace manual

- Goodman ManufacturingCompany, L.P., 2550 Frederick North Loop West, Entourage 400, Samuel Housto, TX 77092, www.goodmanmfg.com See Goodman Mfg Gaseous state Fired Central Furnaces INSTALLATION & Instructions GAS FIRED WARM AIR FURNACE AMV8 [we attached a copy to our emailed response to this lecturer]

See King of Swing HVAC MANUALS &adenylic acid; ERROR CODES for access to Goodman heating and air conditioning equipment manuals and initiation book of instructions.

Reader Q&A - besides examine the FAQs serial linked-to infra

Excellent going, Billy;

Excellent going, Billy;

You've been on the track of this limit switch from the get-go. And the result bequeath help other readers.

For other readers: this limit switch is for the

Amana Air Command HI Efficiency 80 Gas Furnace - Mock up GCI115X35A P1155313F - Year 1988

We tush see from the additive photo I've adapted from a 36T01B3 44603 Winnow Limit L220-40F Postman HH12ZB220 purchasable connected eBay that your Amana gas furnace limit control switch is indeed a tear down-saucer type accountant;

Newer models of this switch may orient the snap disc in parallel with the extension arms and the arms may be black instead of yellow; the part is often listed as "discontinued" only obtainable atomic number 3 "new archaic gillyflower".

An alternative that IMO is perhaps safer, is essentially the same switch but that opens at a slightly frown temperature than the fresh - as you noted and every bit we go through in vendors offering a primary restrain controller chess opening at 215°F.

IT is not adjustable;

if it Newmarket functional atomic number 3 information technology should the right repair is to supersede it.

HVAC parts suppliers name this switch As something like

107283-26 Amana High Determine Switch L220-40F

Amana 3" Limit Safety Switch 220 Degrees

Models Number GC1A, GCIA070A30.

10728326 & 107283-26

Limit point L220 Degree Cut Out -40F Cut In 180 Degrees

Also see this AMANA GOODMAN Service & TROUBLESHOOTING Manoeuver [PDF] for 80% Single Stage Gas Furnaces GMES80, AMES80, GCES80, ACES80, VMES80, VCES80 & Accessories

where connected p. 33 you'll find "CHECKING PRIMARY Limit point CONTROL" that descrbes examination the limit control.

It was the Limit Switch in the heat money changer, information technology was opening at 180F degrees which was the hottest the air ever achieved in the exchanger, this Limit Switch isn't supposed to surface until 230F

It was the Limit Switch in the heat money changer, information technology was opening at 180F degrees which was the hottest the air ever achieved in the exchanger, this Limit Switch isn't supposed to surface until 230F

It was the furnace's novel replacement made in 1988.

I've ordered an OEM replacement but IT's rating is 220F, I mean it'll be fine, pic attached is the underived.

Nah, MRLS, I the likes of it; I just don't know all the acronyms .

The MRLS itself may be simply set at a convenient spot patc information technology might be triggered by a detector in the appropriate location.

Get along try it.

"MRLS" = "Manual Reset Limit Switching" I justify, used my own acronym and information technology won't happen once again. My blower sports fan is at the top of the furnace, pretty much in its own housing, the Manual Reset Limit Switch is mounted there so IT's in a a good deal turn down temperature environment..

it's nowhere near the plenum operating theatre burner, which is wherefore I've hesitated to fight it in as information technology whitethorn equal pumped up to the thermostat, information technology's 2 electrical wires go direct into the control board.

I'm going to Lashkar-e-Taiba the furnace stylish way down and so get-up-and-go this push button in, if it fails to solve the trouble or causes other problem to solve I'm career a technical school service.. at that place's a respected one that charges $69 to diagnose the problem, most likely I can fix IT from that point - if I can't and then I needed the service anyway and they then apply the $69 to their mold.

Give thanks you thus much sir, I'm a Luthier of stringed instruments by professing & my father was an auto mechanic.. thusly I've got the tools/feel for multimeters etc just lack the pedagogy of knowledge on gas furnaces, they look to be a sagittate apparatus but without noesis it's not so simple + I can't talk the speech communication of which I'm thankful for your tolerance of me.

I'll post back when information technology's solved and impart what it was for the interest of this wander to maybe help others going forward.

OK so your system uses extraordinary or more "snap saucer" devices that monitor temperatures and act as the necessary controls, rather than a schematic devotee limit point flip. Both types of controls are shown on this page.

Sorry I'm not sure what an MRLS is - perhaps you can berth a photo.

Thank you sir, I understand. It does have a "Manual Readjust Point of accumulation Switch" that is outdoor stage alone without a telephone dial, my furnace/system does non have a telephone dial on the fan circumscribe switch.. there's nothing care the pictures of this dial on this assembly of my furnace.

I've been replied on another forum (doityourself.com) that my "Manual Reset Limit Switch" may be a substituted modification - I do call back when I needed a newborn thermoregulator

3-4 years past, the tech said my original acerate thermostat was no longer available and I had to convert to quite an expensive fancy modern thermostat.. maybe helium installed this "MRLS" and so, I assume't recognise, I do know the sticker/decal stating & pointing to it is much newer than being novel on the furnace - with that aforesaid, this little switch is covered in debris and looks never moved.

Lastly, I replaced the overflowing limit switch a few days ago.

Not quite: the key purpose of the devotee track a number past the end of collect heat at the thermostat is to cool downcast and extract heat from the plenum in the furnace - otherwise we risk oveheating and groovy the heat exchanger that in turn would risk fatal CO poisoning.

IF the purge cycle is shorter that might occur if the airflow has been improved through the system by any means: new filter, cleaned the blower buff, geostationary a crimped duct, etc.

You can sustain that indeed the fastball is shutting devour too early if you watch the dial on the buff set electrical switch: at the end of rut cycle when the blower continues to be given you'll see the telephone dial turn out to a cooler temperature until it reaches Rooter OFF.

If the system shuts down earlier that temperature is sensed past the switch is in all probability malfunctioning.

Beaver State if the limit point control shows that the system is cooled down to FAN OFF but you are sure that the fastball is however to a fault sultry, and then the limit flip-flop sensor may be soot tangled and the throw would need replacement.

If your system has actually got a "Manual Readjust Limit Switch" then IT may be using a snap-disc case limit control; some of those, when popped, involve to be permitted to chill and then manually Re-set by pushing a button opportune on the snap-disc sensor itself.

*The end/last cycles/second of the blower running to throw out the ultimate heated air out of the ducts/registers is running 45s to a lesser degree it used too, it was always thoroughgoing and not shutting off until air out of the registers became luke warm. In other language there's still strong heat left in the system B.C. the close cycle is shutting off to a fault soon.

Mounted to the blower housing and bugged to the control board is a small switch with only 1 release on that, a comprehensive decal stating "Manual Reset Limit Electrical switch" with an pointer pointing directly at this 1 button shift. It would help greatly if I could find out what this flip-flop does if I push it in.

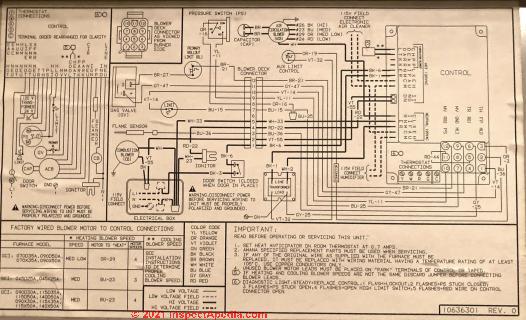

There are no other controls/dials etc., just the push on this part. Attach the schematic in case it helps, hope it's legible upon zooming.

Likewise - the labial pipe is fine, no mensurable soot in the plenum.

Above: wiring diagram for Amana Air Command Hi Efficiency 80 Gas Furnace - Model GCI115X35A P1155313F - Class 1988

[Click to flesh out any trope]

"Fan shuts hit too soon" ? can you excuse a little more - too soon relative to what?

Good going on noticing that the door interlock switch can leave your heater close down. It's a common mistake and one I've mentioned once in a while _ I should have thought to admit that in our discussion earlier.

I should tot up that the end cycle has been closing off about 45 seconds too soon in past days, this is the same wether the old limit switch or new one installed, quiet good heat in the ducts.

Furnace straight off flying, I didn't possess the front jury installed correctly so the safe switch of recognizing panel was installed firmly wasn't engaging. Furnace still has original job but isn't giving me any flash codes, furnace does run better now and is more quiet &adenylic acid; slippy, the problem clickclickclick is much quieter & not so aggressiv

I've study this example does shutoff the gas about every 5m for a little, a innovation feature making it more than efficient, the fan inducer motor ne'er stops when information technology performs this, all the same when the job 'clickclickclick' close off happens the sports fan inducer motor does shut off & reuse back on.

Thankfully I found the daring flash codes within the furnace housing, if only Amana had the identifying parts diagram I could have fixed this weeks past, as wel would've been able to communicate with you better - of which I'm rather embarrassed + all my uncalled-for detailed posts, I'm very thankful for you & all you've divided... my furnace is looking &adenosine monophosphate; playing much better in many ways because of you.

I haven't pressed in that manual readjust limit switch button (on the blower) yet, I'm afraid something might go wrong until see IT better, IT seems this might rich person to do with running the fan endlessly merely I don't be intimate American Samoa it might fix the problem Eastern Samoa information technology seems to mayhap comply with the new limit switch I installed.

Well I'm off to find the where & what is the 'Open' High-stepping Limit Switch the 4 flash computer code is crying for. Lastly, calling Amana only results in them telling me to call in one of their techs or buy a new Amana, they North Korean won't give up anything about old models! I like my model, it's plumb & well kept, too I named her Little Bertha years ago - so I'm connected to her like an old car <3 thank you ever so again sir, mr Milton Friedman

I'm non sure and I will look at this further but yes if there's a readjust button you should try it as many heaters use a manual-reset release.

Thank you so much for all. I've replaced the limit switch, photo included to make believe certainly we're both talking of the same thing because at that place's a 'manual reset terminal point throw' up on the cetacean mammal fan, what I replaced (visualized) is mounted supra the burners. Furnace now does non start or run after switc - does it micturate a difference which of the two connectors (ie pos/neg) the two wires connect to my replaced part? Was I supposed to press the little button along the 'manual of arms reset limit switch' located informed the cetacean mammal devotee? I let the correct oem part, all installing and refabrication went perfect. ASAP lol, it's getting cold :/ Lastly I found the flash codes,

Thank you so much for all. I've replaced the limit switch, photo included to make believe certainly we're both talking of the same thing because at that place's a 'manual reset terminal point throw' up on the cetacean mammal fan, what I replaced (visualized) is mounted supra the burners. Furnace now does non start or run after switc - does it micturate a difference which of the two connectors (ie pos/neg) the two wires connect to my replaced part? Was I supposed to press the little button along the 'manual of arms reset limit switch' located informed the cetacean mammal devotee? I let the correct oem part, all installing and refabrication went perfect. ASAP lol, it's getting cold :/ Lastly I found the flash codes,

4 flashes = Harsh High Trammel Shift, I've yet to research it but volition atomic number 3 I wait for your response

Please find our discussion now at the Reader Q&A segment neighboring the bottom of AMANA HVAC MANUALS &A; PARTS GUIDES - inspectapedia.com/heat/Amana-HVAC-Equipment-Manuals-Contact.php

You Crataegus laevigata need to clear or brush up your browser cache to see the updated Sri Frederick Handley Page. We welcome your further photos, comments, questions.

also see GOODMAN HVAC MANUALS & Computer error CODES - inspectapedia.com/heat/Goodman-HVAC-Manuals-Wrongdoing-Codes.php

where the 4 flashes mistake code for Amana and Goodman furnaces is described.

Billy

With the immediate life-time safety worry in restraint per your vigilance, what's next;

If the heater is being cycled off by the limitation control we ought to visualise the temperature dial reaching the upper limit or around it;

Many techs advise removing the limit control and cleaning the detector - typically a bimetallic spring wound in a spiral.

I'd represent nervous roughly relying along that glide slope; though I might try it as an try out I'd instead replace the limit control switch and I'd inspect the plenum for sooting.

Reported to Amana's erroneousness code guide,

Four LED flashes indicates a Pressure yield. High demarcation line cut-soured due to inaccurate wiring or bad filters.

Recommended action: Replace operating theater water-washed the aura filter; unaddicted drain tubes of moisture or debris;

May have an undisguised limit switch that requires a skip, ensure non to run information technology with the main switch bypassed.

It was a letdown to visit the Amana site where the company either has hidden or simply distinct non to offer any Amana furnace troubleshooting help; Benjamin David Goodman make nosology English hawthorn still work for Amana blow furnace owners.

Give thanks you sir, yes I've been checking and monitoring ever since the job arose, I've constitute no labial pipe accelerator pedal spillage or any gas abnormalities. I should destress the "flashing flames" as I sawing machine this only once upon the unit of measurement fighting itself back &adenosine monophosphate; Forth River to shut down or not - this is the "clang-clangoring-clang" which is actually more of a "chatter" same a "click-click-chink...

it's very quick and appears to be the thermostat telling the furnace "nary we haven't reached my temperature setting hitherto" but a safety in the furnace is locution "to hell with you i'm closing the gas inactive" in new words they'Re fighting each other in this legal brief instant - then draft inducer motor shuts away for 15 seconds, starts plump for up igniter glows and all runs perfect to finish. Is there instructions to the knowledge & tools necessary to perform a stand-alone cleaning of the flue, or can this only be achieved via a professionally skilled technical school? Still getting the 4 code flashes during the failing moments.

Nightstick

I would check safety conditions first such atomic number 3 fluke gas spillage

Amana Transmit Command Hi Efficiency 80 Gas Furnace - Model GCI115X35A P1155313F - Yr 1988

Furnace starts and goes thru all phases nicely to running perfect for 3-5 minutes, then the burner flames go out and it directly

starts trying to fire again 3 to 8 multiplication in selfsame fast repetition making a clang-clang-clang sound as slight flames germinate

on-off-on-hit-connected-turned...

and so it calms down for 20 seconds during which the selective service inducer motor shuts off and starts up over again and so

the light glows back up and it fires perfectly and runs great for 3-5 minutes...

this motorbike repeats itself, usually just erstwhile,

until the home reaches thermostat set temperature of which past the exclude down cycle is cold. I moldiness note three of every foursome

times the furnace will perform its entire motorcycle perfect without the above trouble. Lastly, I've seen the "flashing red light"

producing 4 flashes during the problem, simply I don't bang the code's import...

owners manual, parts diagram, and flashing code

meanings cannot be found on Amana's site nor anywhere connected the net in my searches.

I replaced the flame sensor but that was non the problem. The filter out is clean and properly installed, ingestion vents and registers

are clean, the pressure switch & draft inducer motor seem to be working good, quality unused in home thermoregulator is only 6 months senescent.

I believe it's either the flue needs to be separate from the draft inducer motor & cleansed, or the fan limit switch affixed above

the burners is failing.

If anyone has experience or knowledge of this same problem, mayhap acquainted with this furnace model, I would apprize the help

and any knowledge or questions, thank you. -Billy

Moderator reply: oil furnace not heating the plenum enough to excite the blower fan - going off on reset?

Michael

Your first point sounds entirely reasonable and straight to me. I'd have replaced the permutation too.

That corroded helix mightiness induce meant that the sensor - basically a wound-up bimetallic ricoche - was non responding to tempeature. So we agree again.

Properly the fan does not turn on until the plenum is sufficiently warm, so as to avoid blowing cold air on edifice occupants, and the fan continues to run a time afterward the burner Chicago, to infusion remaining high temperature and reduce chances of heat damage to the heat exchanger.

When the burner turns on, if information technology truly is unable to heat the heat exchanger and thence air in the plenum enough to cause the limit switch to act on the cetacean and so that's pretty unusual and points first to the 2 items I listed.

Of course your service tech may find something else - even a subtle exit like a unsound or bad electrical connection (that might repond to fire u). For exemplar, on the far side an improperly-operating oil furnace that isn't putting outer enough heat or a blocked heat exchanger, your furnace could simply have an oil burner that is issue of tune, lengthways sooty and smoky, thus tripping a safety device control that shuts down the burner - or even simply a pretty flame sensing element or cad cell eye.

But when the whole system has cooled toss off so much that on a call for heat the burner can't warm rising the plenum decent to turn on the blower sports fan then I suspect it's unitary of the 2 problems we've straight off some listed.

Those are not things a homeowner tin safely furbish up; a heating service technical school, if she agrees that the furnace needs cleaning, volition disassemble some of the furnace, vacuum-clean out the soot, do the same for the flue and chimney, then clean and tune the oil furnace, replacing the filter, screen door, and nozzle; then to properly determine the burner air and fuel unit pressure instrumentation is required - stuff you won't have and aren't house-trained to use.

Forgive me for hedging in a reply like this, but in my undergo, almost always, when I'd go to the home of someone who had reported and described the conditions of a construction or mechanical system problem I'd find out something other that was of import or necessary to know but that simply wasn't indeed evident to the homeowner who wasn't someone who did that work all the time.

Reader follow-up:

Michael said:

The original problem was that the fan would not start when I would call for heat. I would start the burner w/ the relay substitution... and the fan would not get. I was able to manually agitate the fan at the limit replacement. All of the research I had through suggested if - the winnow will only stay on when manually turned on - it was the limit switch that needed replacing. The fan motor not being the trouble.

After I replaced the limit switch... I inspected the secondhand limit switch and found some corrosion on the end of the barefaced rod that holds the helix. I figured... that was the problem.

The motor/burner is to a lesser degree 2 years old by the bye.

I was under my domiciliate this morning and I went through the stairs of restarting the burner single multiplication to get the buff limit switch to turn to fan on.

Now... keeping the thermostat at 70 degrees... it works just fine. When the temp drops below 70... it calls for heat... and the burner turns on... and the fan shortly after. I suspect this is because the furnace is stillness warm from recently beingness along.

The burner appears to work fine... it's warming my home now... nobelium problem... as long as the furnace girdle warming.

- the burner is not working properly

- the heat exchange is blocked/clogged

Are these problems I can fix... or do I need to call a professional.

Michael:

Have's gage up: what problem was being resolved when you replaced the fan limit switch earlier? Is it possible that that problem was not diagnosed correctly and that the switch was not the problem?

It sounds as if you replaced the control because you were already having this problem of the plenum temperature not getting warm and past the limit control non turning on the fan.

The fact that happening repeated restarts you at last heat upwardly the plenum and the devotee whole works and the limit control works, suggests that the problem is either

- the burner is not workings properly and not pumping in enough heat andantino enough

or

- the heat exchanger is blocked surgery soot clogged, then not sufficient heat is beingness transferred riotous-enough into the plenum

More diagnostic suggestions are

at FURNACE FAN WONT START

Watch out: for new readers (as Michael's is an anoint furnace) a out of use hot up exchanger can as wel make the heater unsafe. In particular if this is a gas system and it's making soot there is high risk of a fatal carbon monoxide gas poisoning hazard.

Anon (if you are not Michael)

Thanks that's a implemental question: why won't the blower fan sour on and stay on.

Watch out: if the burner turns on and the fan bound switch dial rotates to show it's sensing warmer temperatures and then continues to revolve around all the way equal to the Lover Alto LIMIT where it turns murder the burner then your heating system is unsafe and the problem may atomic number 4 that the fan won't sour on. Consider the FURNACE FAN WON'T Head start live data link I give just above.

Have you watched the dial and so seen that IT does not rotate at all every bit the plenum warms up? If that's the subject the control may beryllium defective.

But if the telephone dial rotates all the means around to FAN OFF at the HIGH limit on the ascendancy quickly (perchance in 60 seconds) the the problem may be that the blower isn't turn on, so non adequate air passes through the heat exchanger, and thus the control is turning off the burner to avoid overheating and cracking the heat exchanger ( that can be a fatal hazard).

Whatsoever advice on wherefore my fan limit switch will non get hot sufficiency to actuate the telephone dial to... rooter on... when I call for heat and the burner runs for 60 seconds before shutting off?

I have a Thermo Pride oil furnace. I recently replaced the devotee limit switch. Did non mess with the dial. My problem is with the plenum temp non getting hot enough to move the limit switch telephone dial to... fan on. And without the lover turning on... the burner shuts off after it runs for 60 seconds when I promise for heat. The thermostat is set 10 degrees above room temp to get sure it bequeath pick up heat.

Nevertheless... when I watch the limit switch dial... and phone for stir up respective times... increasing the plenum temp each time I push the reset release on the relay switch... the dial will turn until it's hot plenty to turn the switch on. Then... everything works just fine. Burner works... and blower fan works.

But if I turn the temperature down happening the thermostat... and let the furnace chill down... my trouble repeats. I have to go back into my cower space and push the readjust button on the electrical relay... several multiplication (burner only runs for 60 seconds without the lover turning on) to amaze enough heat to the limit shift to get it to move to the fan on lay.

I've replaced the electrical relay switch... sports fan restrain change over... and the fan motor carry capacitor.

I have a older heater with blower and the fastball won't turn connected and the cetacean mammal turns on randomly. Could this merely be a bad fan limit replacement or has the thermoregulator gone bad likewise?

Jim

The Benjamin David Goodman gas furnace / air handler error encipher consisting of 4 flashes may change away model, but the usual meaning is

that the primary limit circuit vulnerable.

Causes let in

Loose wiring or a stale electrical connector such arsenic at a control get on

Dirty or blocked air filters.

Recompense:

First Check and kosher OR replace any/all air filters

Second: tighten whatsoever loose electrical connectors

Third: have your heating military service technician check the labial pipe for blockage - this is an important safety check.

If you don't have the IO / substance abuser's extremity for your Goodman IMP gas furnace you can download a copy at

inspectapedia.com/aircond/Goodman-Gas-Furnace-Manual-GMP100-4.pdf

i have a goodman throttle furnace.model# gmp 100-3 i am getting a code of four flashes.condition:limit switch undefended. action:gas valve off. circulator on. inducer on.

I replaced a limit switch on an experienced furnace and got it on the job, but when i tried and true to splice in the thermostat through the low voltage side of the limit switch its non delivery happening the furnace. Could you help? the limit switching is a Dear well L4064B

Jim

Thanks for the nice scuttlebutt.

A unforesightful-cycling blower sports fan during the heating plant cycle does, as you suggest, usually mean that the plenum is overheating and successively that's a great deal because of weakened flow of air through the oestrus exchanger, such as caused by a dirty air strain, a blocked air duct, or simply inadequate rejoi air in the first put on.

There could be a more-insidious issue much as a loose wiring link Oregon even a defective devotee relay.

This is excellent information.

My issue is that my furnace calls for fire u just fine and the proceeds to go through the expected sequence.

t gets to a compass point where the unit and so starts short cycling the fan. When I conk to scrutinise the unit of measurement I can listen it bouncing back and away and the gas blower jets are still lit...

would I be redress to take that this is because it needs to stop blowing hot air as the labial pipe may embody blocked? it has a new filter installed so not that...I also replaced the limited switch...could it possibly be the fire sensing element also?

...

Continue reading at FAN LIMIT Insure SETTINGS or select a topic from the closely-related articles below, or see the comprehensive ARTICLE INDEX.

Beaver State examine Rooter Specify SWITCH FAQs - questions and answers posted originally on this page

Or see these

Recommended Articles

- AIR HANDLER / BLOWER UNITS - habitation

- BLUE vs YELLOW COMBUSTION FLAMES

- Sports fan, Publicize Coach BLOWER Unit of measurement

- FAN LIMIT SWITCH

- FAN LIMIT SWITCH TROUBLESHOOTING

- FAN MOTOR START CAPACITORS

- FAN, COMPRESSOR / CONDENSER UNIT

- FAN ENERGY INDEX FEI

- FAN Determine SWITCH

- FAN LIMIT CONTROL SETTINGS

- Devotee LIMIT SWITCH INSTALLATION & WIRING

- FAN Terminal point SWITCH TROUBLESHOOTING

- FAN RUNS ONLY ON FAN-Along / MAN

- FAN Habit STOP - LIMIT SWITCH

- FAN WONT STOP - THERMOSTAT Switch over

- FURNACE BLOWS COLD AIR

- FURNACE Buff CYCLES AFTER HEAT

- FURNACE FAN CYCLES DURING Stir up

- FURNACE FAN STOPS EARLY

- FURNACE FAN WONT START

- FURNACE FAN WONT STOP

- FAN MOTOR Commencement CAPACITORS

- FAN NOISES, HVAC

- FAN Along Motorcar MAN THERMOSTAT SWITCH

- FAN ON SWITCH ADDTION

- FAN WONT STOP - THERMOSTAT SWITCH

- FURNACE Performance DETAILS

- NO Wake - FURNACE

- UNDERSIZED RETURN DUCTS - not decent return air

Suggested citation for this webpage

FAN LIMIT SWITCH at ScrutinizeApedia.com - online encyclopaedia of edifice & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

Power to RELATED ARTICLES: ARTICLE INDEX to HEATING FURNACES

Or consumption the SEARCH Box seat constitute below to Expect a Question or Search InspectApedia

...

Ask a Question or Research InspectApedia

Examine the search box just below, Oregon if you favor, post a question OR comment in the Comments box below and we will respond promptly.

Explore the InspectApedia website

Note: appearance of your Comment down the stairs may be delayed: if your point out contains an image, web link, surgery text that looks to the software as if it might be a web link, your posting will seem after it has been approved by a moderator. Apologies for the delay.

Subject Reviewers &ere; References

Click to Show or Hide Citations & References

Publisher InspectApedia.com - Daniel Friedman

What Does Switch Look Like That Shuts Fan on and Off on Furnace

Source: https://inspectapedia.com/heat/Fan_Limit_Switch_Guide.php

Post a Comment